Unknown Facts About Caster Manufacturer

Wiki Article

The Main Principles Of Caster Wheel Manufacturer

Table of ContentsCaster China - An OverviewAbout Caster ChinaThe 8-Second Trick For Caster ChinaRumored Buzz on Caster ChinaNot known Details About Casters Supplier

If you are buying casters as an add-on accessory to your piece of equipment, right here are some aspects you will need to take into consideration. Softer floor types, such as wood, will certainly require softer wheel materials while more difficult floor types, such as concrete, can handle more challenging wheel materials. If your work space is damp and/or oily, or if direct exposure to chemicals is a concern, it is very important to select wheel materials that will have the ability to take care of these problems.However, if you need to maneuver a cart or piece of devices in a tight space, a swivel caster is most likely the better alternative for you. The larger the tons ability is, typically the more challenging wheel product as well as bigger wheel size you will need. Usually, the greater the wheel size is, the quieter the wheels will certainly be.

If you need to safeguard the device after relocate, then you must look right into buying stopping or locking wheels. Often only having 2 out of the 4 casters with brakes is enough for your system. Suitable for foodservice areas and food manufacturing centers, NSF-rated wheels are constructed to stay hygienic in atmospheres where the casters will certainly be often subjected to washdowns, oils, or chemicals.

The Facts About Caster Manufacturer Revealed

are durable due to the fact that they do not have air inside, so you do not need to stress over flats. They offer good flooring protection and also a silent operation, making them a wonderful choice for softer flooring types. function a solid, sturdy style. They are corrosion- and also corrosion-resistant, making them a sanitary alternative for damp environments.

5 Easy Facts About Caster Manufacturer Shown

While both are wonderful for different applications, the kind of install you need will mostly depend on what you are to. feature a flat brace with screw openings that allows the wheel to be flush-mounted to the tools. Pros Plate has a bigger area than threaded stem place for even more reputable stability and also movement Suitable choice for heavy-duty equipment Disadvantages Not as very easy to change as stem install casters include a single stem that are commonly screwed right into the tools to connect it.The design of wheel that is best for you depends on the level of ability to move your piece of devices needs. Pros Perfect for moving products direct Easier to control as well as no steering needed Great for heavy loads Disadvantages Can just relocate forwards and in reverse, so they may not appropriate for tight spaces Pros Able to swivel 360 degrees so they can relocate any instructions Best suited for turning dilemmas as well as in tiny areas Some feature swivel locks to make straight-line and long-distance taking a trip easier Cons Harder to control and navigate the wheels to enter the very same direction Not optimal for larger tons or cross countries considering that even more workforce is required to control the lots Understanding what dimension you need is also vital when selecting a caster.

Here are the 3 measurements to examine for to ensure you acquire appropriately sized wheels. the distance from the base of the wheel to the top of the leading plate or wheel stem. the range in between the contrary sides of the wheel. Casters are normally labeled by their wheel size.

The 9-Second Trick For Casters Factory

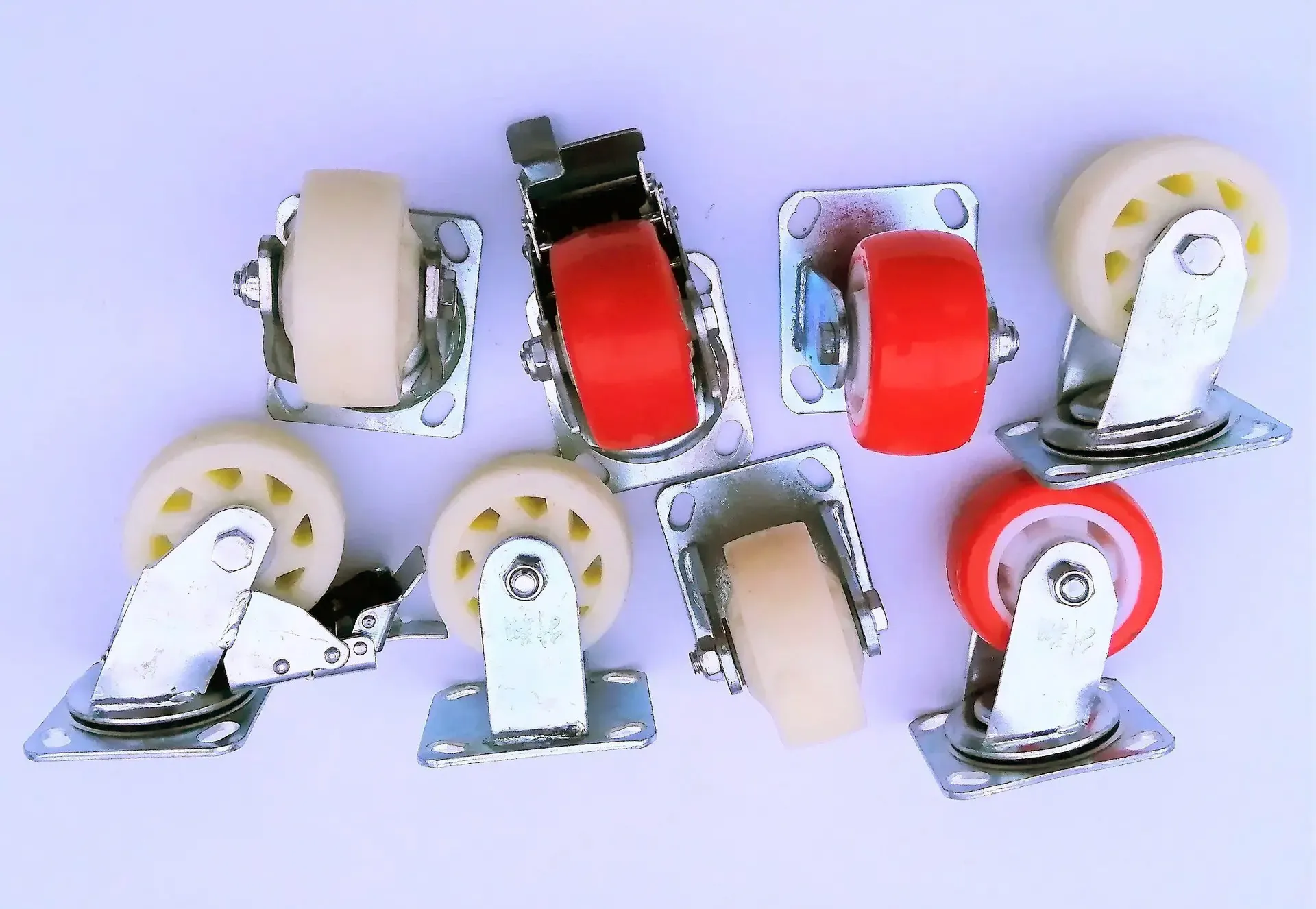

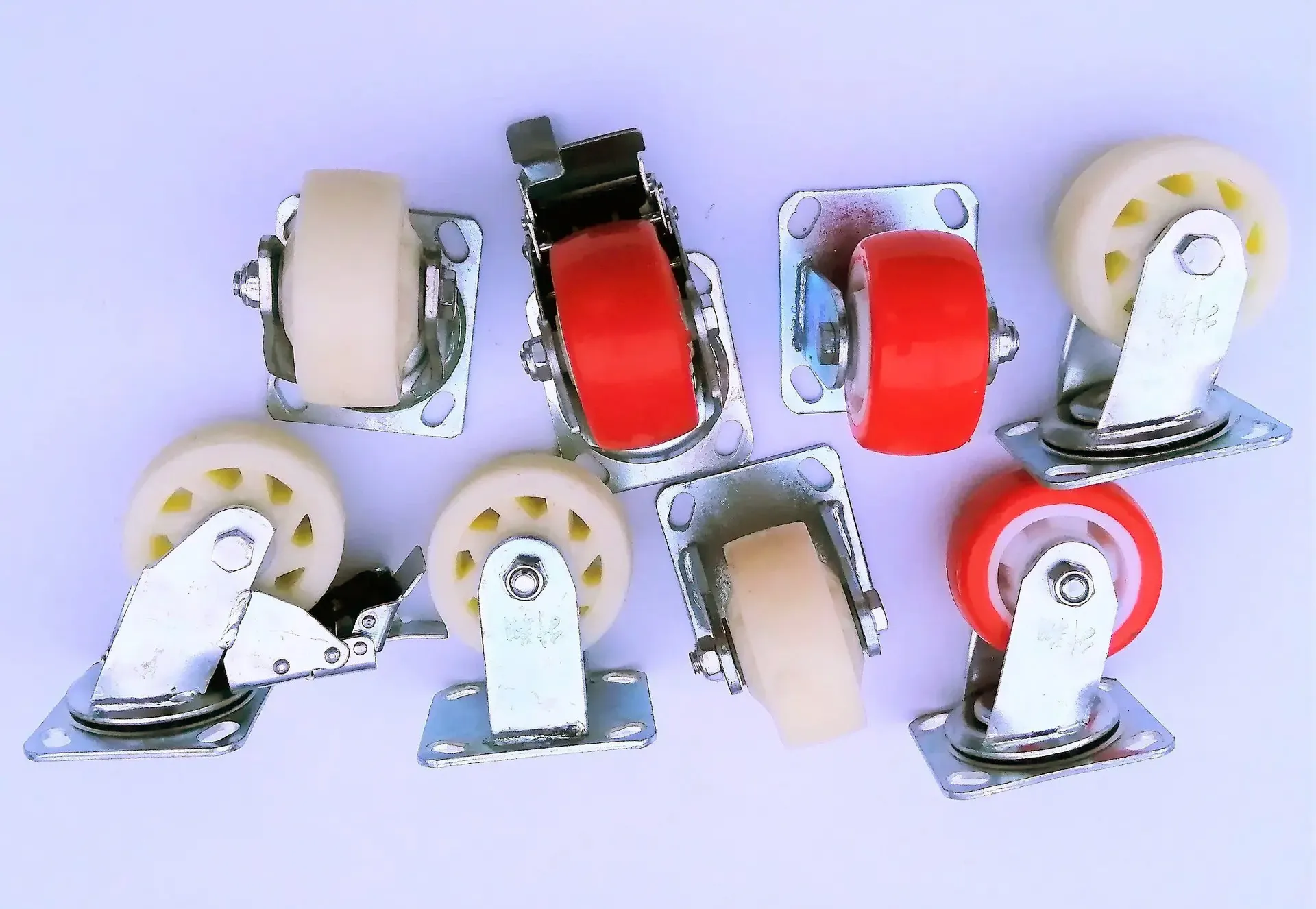

A caster is even more than simply a wheel; it's a flexible rolling device that consists of a wheel as a well as a placing structure. As received the photo to casters supplier the left, casters consist of a single wheel housed within a frame. They are regularly used on the base of chairs, workbenches as well as heavy equipment, enabling these products to roll efficiently across the flooring.One of the most common kind, plate casters are characterized by a flat, square-shaped placing surface. They typically have 4 holes one on each corner of the mounting surface area which are made use of to safeguard the plate caster to the item. They are called "plate wheels" because the mounting surface resembles as a square-squared plate.

The smart Trick of Caster China That Nobody is Discussing

While plate casters have level, square-shaped placing surface area, stem wheels feature a cylindrical-shaped rod for installing. In the photo displayed above, the wheel in the center is a stem wheel. The cylindrical-shaped pole is put inside an object's installing port of the same sizes and shape. Some stem wheels include a threaded rod, whereas others include plain round poles.Hollow Kingpin wheels are defined by a stemless design with a hole on the top of the mounting surface. To mount a hollow Kingpin caster, the caster is placed against the item, after which a bolt like a screw or screw is driven through the opening and into the things (caster wheel manufacturer).

Unlike other wheels, inflexible casters can't pivot in a total 360-degree variety. Stiff wheels are typically stronger than standard casters, but their minimal range of movement makes them an inadequate option for certain applications.

Report this wiki page